|

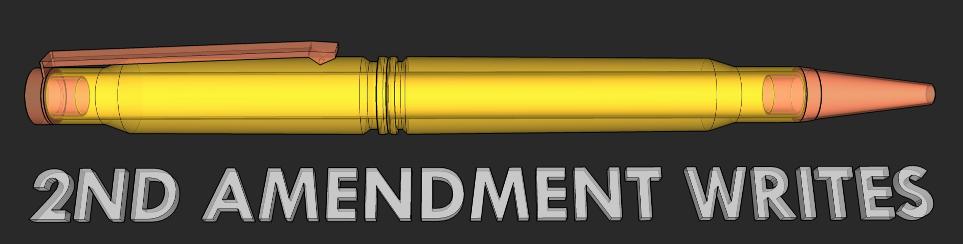

SUPERIOR QUALITY BULLET PENS |

The process - TO STAY UP TO DATE, LIKE MY FACEBOOK PAGE |

|

Well, there you have it.? You can see all of the equipment, material steps and time that goes into making these unique, superior quality bullet pens.? If you want to make them yourself, all you need is a couple thousand dollars worth of equipment and materials, strong attention to detail, patience, humility and a bunch of spare time.? You would probably charge more for the pens once you experienced how much goes into them first hand.? On second though, you could just buy them from me!? Besides, you haven?t even seen how much work goes into the packaging yet! |

|

There are others out there that make bullet pens that may look similar to mine, but in terms of quality, fit and finish, detail and durability, these pens stand far above the rest. This page is to show you how much planning, research, effort and care go into making these implements.

I begin by sourcing virgin brass and nickel plated brass for the pens.? I use the highest quality newly manufactured Nosler Custom brass and Remington nickel plated brass.? I could use once fired cases, but I often find that most of the cases have unsightly deep scratches or dings from being ejected.

I then inspect those cases for visual or structural defects.? Even with newly manufactured brass this leads to a rejection of anywhere from 5% to 25% of the cases.

After inspecting and sorting the brass, I lube them and run them through a full length resizing die on a reloading press.? This makes the necks very uniform in concentricity as well as size.? This process can lead to further rejection of cases as too much lube on the case or in the die will actually dent the side of the case. |

|

The next step is to drill an accurately centered and concentric hole in the bottom of the case.? This in itself is a multiple step process involving many tool changes as well as careful alignment in order to get precise and repeatable holes.? If the hole was not centered, the halves of the pen would wobble as you twisted them. The hole is started with a center bit, which is specifically designed to leave an accurately centered hole for a drill bit to start in. |

|

The hole is then enlarged for clearance using a drill bit.? When it comes to machining, drill bits are not as precise as most would think.? This leads to a few more steps before reaching the final result. |

|

After the drill bit provides a clearance hole, I use a chamfer bit to provide a pocket for solder later on as well as to create a guide for my last operation. |

|

The last step is to create a precisely concentric hole which is accomplished by using a reamer. |

|

I am now left with an accurately centered hole as well as a concentric one. |

|

The next step is to prep the case for a brass tube insert.? I originally started using heat shrink as a bushing of sorts to fill the void between the outside of the smaller diameter brass tube and the case.? I am one of the few making these pens that actually uses a specially designed brass bushing.? There are a couple of reasons that I go through the effort.? The main reason is that the heat shrink material is rubbery which make the tip move under the pressure of writing.? A tip that moves around is not a sign of quality.? The other reason is to have a perfectly centered tube and therefore a perfectly centered tip. I use CA glue to glue the brass bushing in and then us the glue to hold the brass tube in temporarily.? CA glue is a short term solution with brass bullet pens as it will eventually fail. |

|

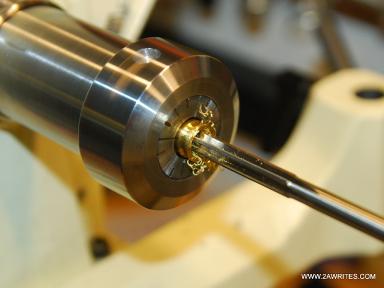

Now for the really important part and yet another step that sets my bullet pens apart.? Other bullet pens you may see around will have CA glue as the binding agent used to keep the brass tube inside the case at the bottom of the case.? CA glue will fail, especially if the tip is able to move which puts constant force on the brass tube.

I use lead free silver solder to hold the brass tube in place.? It is more difficult, more time consuming and more costly.? If you haven?t noticed yet, none of those side effects are a good enough reason for me to compromise the durability and quality of my bullet pens.

This is also a critical step where the tube has to be perfectly centered. |

|

Once the tube is finished being soldered, I trim the excess brass that sticks out.? I also ream the brass tube to ensure proper clearance for later on as well as I hand spin the brass cases on a mandrel to verify that the brass tube is indeed centered. |

|

The finish on my bullet pens is also something that I?ve had to learn through a lot of trial and error.? All of my bullet pens are polished on the lathe.? Here is the process for the nickel plated brass. |

|

The brass finished cases go through one more step.? I apply a high gloss friction sealer on them to keep them looking great when you get the bullet pen.? This coating will eventually wear off but is typically replaced by oils from your hands. |

|

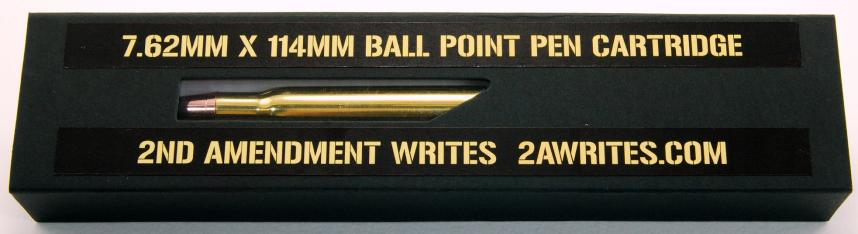

At this point I?m nearly done.? Now I press in the accent tip, clip and end. |

|

The last step is to press in the twist transmission (mechanism).? Yet again, this is something that sets my pens apart from the rest.? I spent a lot of time and money learning, researching, ordering and testing the various twist transmissions that are out there.? Most twist transmissions are too easy to turn or are very inconsistent in the amount of force required to turn them.? I have found a source for high quality, consistent twist transmissions that have just the right amount of resistance.? Think of it like drawers you might find in a kitchen, some open fast, roll out and slam shut.? Really nice kitchen drawers have a good weight to them, slide out smoothly and slow down right before they close quietly.?? My bullet pens won?t twist for you, but they do have a detent (position of resistance) right before they are fully rotated in either direction and will feel just right.

This step also pains me the most as the transmissions can crush if the brass tube has too much resistance when pressing them in.? A diameter difference of just 0.002? (Half the thickness of a piece of copy paper) can be enough to cause the transmissions to fail.? If the transmission fails, I have to use specially sized punches and a vise with non marring pads in order to remove the tip, then a larger punch to hammer out the transmission.? This can lead to scratching or damaging the case, which is particularly painful after having invested so much time and material into it. |